Address

3690 North Church Ave.

Louisville, Ms 39339

In a recent episode of Port Update, Robert Taylor—President and Chief Operating Officer of Taylor Machine Works—sat down with Port of Long Beach CEO Mario Cordero to discuss the company’s commitment to American manufacturing, the evolution of zero-emission cargo handling equipment, and Taylor’s expanding global footprint. The conversation highlighted not just Taylor’s legacy, but also the strategic innovation driving the company forward.

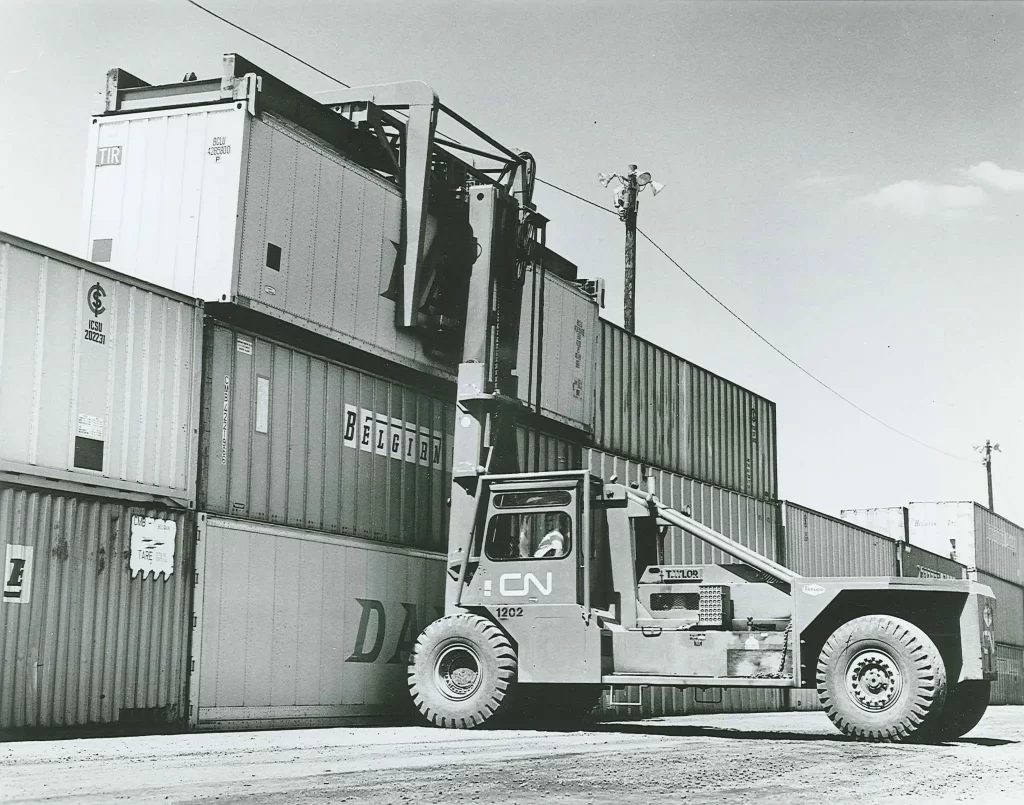

Taylor Machine Works, founded in 1927 by Robert’s grandfather, has grown from a local Mississippi machine shop into a leading name in heavy-duty material handling equipment. With four generations now involved in the business, Taylor’s roots in American soil run deep, and its influence spans ports and industries across the world.

For decades, Taylor has supplied rugged and reliable equipment to ports along the West Coast—including the iconic top handlers, empty container handlers, and reach stackers in operation today. Robert Taylor shared how firsthand experiences on the docks in his youth helped shape Taylor’s customer-focused engineering approach.

As the Port of Long Beach continues to advance its “Green Port Policy,” Taylor has answered the call with cutting-edge electric cargo handling machines. The company’s second-generation battery-electric top handler now runs two full shifts and charges completely in just four and a half hours—with no opportunity charging required.

Taylor’s recent joint venture with Terberg also brings fully electric terminal tractors to U.S. ports, another leap toward sustainable logistics solutions.

Taylor proudly manufactures its machines in Louisville, Mississippi. With U.S.-based battery partner Proterra, the company meets Buy America and Build America standards—making it the only compliant manufacturer of its kind. This level of domestic integration not only supports American jobs but strengthens supply chain resilience in an uncertain global climate.

While Taylor remains firmly planted in Mississippi, its global presence is rapidly growing. With strategic locations across Latin America and the recent acquisition of CVS Ferrari in Italy, the company now supplies and supports equipment in more than 30% of international markets.

Robert Taylor emphasized, “We’re going global—but we’re still doing it the Taylor way: listen to the customer, build it right, and back it with unmatched support.”

Taylor’s approach to growth includes ongoing investment in workforce development, engineering innovation, and partnerships with institutions like Mississippi State University. Robert also discussed the importance of pro-business tax policy, streamlined regulation, and infrastructure investment to maintain momentum in American manufacturing.

Robert closed the conversation with heartfelt appreciation for the port operators, longshoremen, and marine terminal teams that rely on Taylor equipment every day.

“We design and build what you need. And we’ll keep doing that—if you’ll have us.”

Watch the full episode above to hear the entire conversation.

For more on our zero-emission innovations and global service support, explore taylorforklifts.com/battery-electric.